Concrete Drain Blocks in Bangladesh (2025) – Strong, Durable & Sustainable Solutions

Shaping the Future of Drainage Infrastructure in Bangladesh

In a country where heavy rainfall and seasonal flooding are common, effective drainage infrastructure is essential for urban safety and sustainability. Bangladesh’s rapid urbanization — from Dhaka to Chattogram — has placed immense pressure on existing drainage systems, many of which struggle to handle today’s water volumes.

That’s where concrete drain blocks come in. These modern, precast solutions are transforming how Bangladesh manages rainwater, road runoff, and industrial drainage. Designed for strength, longevity, and environmental balance, concrete drain blocks are becoming a cornerstone of the nation’s sustainable infrastructure movement in 2025.

Concrete drain blocks are precast concrete units designed to form efficient, long-lasting drainage systems for both urban and industrial applications. Unlike traditional open brick or cement drains, these blocks are precision-molded for structural uniformity, strength, and easy installation.

Each block is manufactured using a vibration compaction process that combines cement, sand, crushed stone, and sometimes recycled materials like fly ash or slag. Once cured, these blocks offer superior durability against heavy loads, erosion, and extreme weather conditions.

Composition of Concrete Drain Blocks

- Cement (Ordinary Portland or Portland Composite Cement)

- Fine and coarse aggregates (crushed stone chips, sand)

- Water and admixtures for workability

- Optional materials – Fly ash, slag, or recycled aggregates (for eco-friendly variants)

These ingredients make them not only stronger than traditional drainage channels but also more sustainable and cost-effective over time.

Why Bangladesh Needs Better Drainage Solutions

Every monsoon season, millions of Bangladeshis face urban flooding due to poor drainage planning and outdated materials. Traditional cement drains often:

- Crack under load or pressure.

- Allow water seepage, leading to road damage.

- Require frequent repairs due to erosion.

According to local infrastructure studies, Dhaka alone loses billions of taka annually due to waterlogging and road repair costs. Concrete drain blocks solve these problems with their load-bearing capacity, modular design, and quick installation.

They help channel stormwater efficiently, prevent standing water, and minimize long-term maintenance costs — all vital for Bangladesh’s climate-resilient future.

Types of Concrete Drain Blocks in Bangladesh

| Type | Description | Ideal Application | Durability (Years) |

|---|---|---|---|

| Precast Concrete Drain Blocks | Factory-made with consistent quality and dimension. | Urban and roadside drainage | 25–30 years |

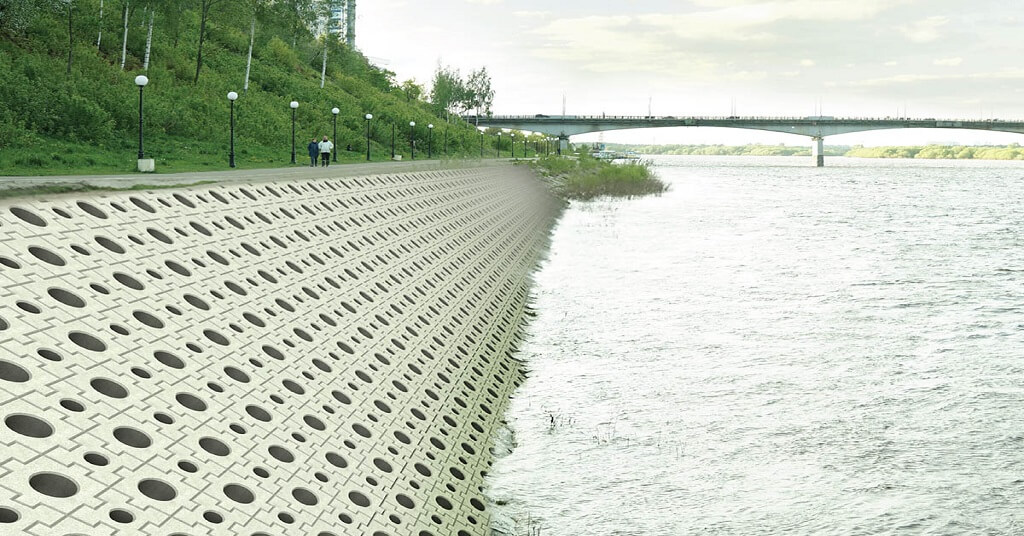

| Perforated Drain Blocks | Allow slow filtration of water into the ground, reducing runoff. | Landscaping, green projects | 20–25 years |

| Reinforced Concrete Drain Blocks (RCC) | Include steel reinforcement for high structural strength. | Heavy-load or industrial areas | 35–40 years |

| Eco-Friendly Drain Blocks | Made from fly ash or recycled aggregates for low carbon impact. | Sustainable infrastructure | 25–30 years |

Each type serves a different function but shares a common goal: efficient water management and long-term durability.

Advantages of Concrete Drain Blocks

Modern infrastructure demands materials that are strong, efficient, and sustainable. Concrete drain blocks offer all three — plus the added benefit of quick installation.

Key Benefits

- ✅ High Compressive Strength: Withstand traffic, machinery, and heavy loads.

- ✅ Long Lifespan: Lasts 25–40 years with minimal maintenance.

- ✅ Modular Design: Easy to install, replace, or extend.

- ✅ Cost-Effective: Reduces recurring repair and maintenance costs.

- ✅ Eco-Conscious: Manufactured using recycled materials and low-energy processes.

- ✅ Smooth Water Flow: Reduces blockages, sedimentation, and overflow.

In short, they deliver superior performance and sustainability in every major project — from residential colonies to industrial drainage systems.

Concrete Drain Blocks vs. Traditional Drainage Systems

| Feature | Concrete Drain Blocks | Traditional Drains |

|---|---|---|

| Installation Time | Fast (Precast & modular) | Slow (On-site casting) |

| Durability | 25–40 years | 10–15 years |

| Water Leakage | Minimal | Frequent |

| Maintenance Cost | Low | High |

| Eco Impact | Recyclable, low emissions | High emissions from cement curing |

| Quality Control | Factory tested | Inconsistent on-site quality |

Verdict: Concrete drain blocks not only perform better — they last longer and help Bangladesh move toward eco-resilient infrastructure.

Price of Concrete Drain Blocks in Bangladesh (2025 Update)

With demand rising across urban and industrial projects, prices vary based on material strength, size, and finishing.

| Type | Size (mm) | Average Price (৳/Piece) | Use Case |

|---|---|---|---|

| Standard Concrete Drain Block | 300×300×600 | ৳150 – ৳220 | General drainage |

| Reinforced RCC Drain Block | 400×400×800 | ৳250 – ৳350 | Industrial use |

| Perforated Drain Block | 300×300×400 | ৳180 – ৳260 | Landscaping |

| Eco-Friendly Fly Ash Drain Block | 300×300×600 | ৳160 – ৳230 | Green projects |

Factors Affecting Price:

- Raw material and cement quality.

- Load-bearing capacity and wall thickness.

- Molding technology and curing process.

- Transportation distance and project volume.

💡 Tip: Buying directly from manufacturers like RCPL ensures you get factory rates and verified strength certification.

Sustainability and Environmental Benefits

Concrete drain blocks support Bangladesh’s national environmental goals by reducing waste and energy consumption during production.

How they promote sustainability:

- ✅ Use of fly ash (a by-product of power plants) reduces landfill waste.

- ✅ No kiln burning, hence no air pollution or deforestation.

- ✅ Long life cycle reduces material replacement frequency.

- ✅ Fully recyclable after use.

- ✅ Compatible with green city infrastructure projects.

These qualities align with SDG 11 (Sustainable Cities) and SDG 13 (Climate Action), helping Bangladesh transition to a low-carbon construction economy.

Real-World Applications Across Bangladesh

Concrete drain blocks are now standard in multiple sectors due to their strength and versatility.

Common Applications:

- Roadside Drainage: Managing rainwater flow on highways and streets.

- Industrial Drainage Systems: Handling wastewater from factories and warehouses.

- Residential Projects: Compact drainage solutions for housing communities.

- Urban Flood Management: Integrated systems in city planning for rainwater control.

- Public Infrastructure: Parks, bus stations, and airports where clean drainage is critical.

Projects under RAJUK, LGED, and PWD have adopted RCPL-manufactured drain blocks to achieve better durability and compliance with green construction standards.

FAQ

Concrete drain blocks are used to build stormwater and wastewater drainage systems in cities, roads, and industrial zones. They help channel rainwater, prevent flooding, and protect road foundations from water damage — making them essential for urban infrastructure in Bangladesh.

High-quality precast concrete drain blocks can last 25–40 years, depending on load capacity, installation quality, and maintenance. Manufacturers like RCPL ensure durability by using vibration compaction and ISO-tested raw materials, resulting in long service life even under heavy rainfall and traffic conditions.

As of 2025, the average concrete drain block price in Bangladesh ranges from ৳150 to ৳350 per piece, depending on size, design, and load-bearing strength. Bulk orders from trusted suppliers such as Rupshi Concrete Products Ltd (RCPL) offer better factory rates and custom sizing options.

Precast concrete drain blocks offer faster installation, higher durability, and less maintenance compared to on-site cast drains. They are factory-made with precise dimensions and uniform strength, ensuring smoother water flow and preventing cracks, erosion, and frequent repairs common in traditional drainage systems.

Yes, modern concrete drain blocks are environmentally friendly. Many Bangladeshi manufacturers use fly ash, slag, and recycled aggregates, reducing cement consumption and carbon emissions. These materials align with green building standards and help achieve sustainable development goals (SDG 11 & 13) for urban resilience.

Rupshi Concrete Products Ltd (RCPL) is one of Bangladesh’s top manufacturers of high-quality concrete products, known for innovation and reliability in infrastructure development.

What Sets RCPL Apart

- Advanced Manufacturing: Automated vibration compaction technology.

- Quality Assurance: Every block tested for compressive strength, water absorption, and uniformity.

- Eco-Friendly Materials: Use of fly ash and recycled aggregates.

- ISO-Certified Facility: Ensures consistent quality across all products.

- Nationwide Delivery: Supply network across Dhaka, Savar, Chattogram, and beyond.

- Project Customization: Tailored drain block sizes and shapes available for civil contractors.

RCPL continues to partner with national and international agencies to supply sustainable concrete products that strengthen Bangladesh’s infrastructure backbone.

Challenges and The Road Ahead

While adoption is increasing, the use of concrete drain blocks still faces a few challenges:

- Limited awareness among small contractors.

- Initial cost comparison with outdated materials.

- Lack of skilled installers in some rural areas.

However, with growing government emphasis on green infrastructure and corporate ESG commitments, these blocks are projected to dominate the market by 2030.

Future trends include:

- Smart drainage systems using sensor-equipped precast blocks.

- Greater integration of recycled materials.

- Expansion into rural development and highway modernization projects.

Building a Resilient, Sustainable Bangladesh

Concrete drain blocks represent more than a construction product — they symbolize Bangladesh’s shift toward durable, eco-conscious infrastructure.

From flood-prone cities to industrial hubs, they ensure clean water flow, structural reliability, and long-term savings.

With companies like RCPL leading the innovation, these blocks are redefining how Bangladesh builds for tomorrow.

“In a climate-challenged world, every sustainable block counts — and Bangladesh is building its future, one concrete drain block at a time.”